Transforming old into new: Volkswagen Group Components commences battery recycling

Last Friday, Volkswagen Group Components opened the Group’s first plant for recycling electric car batteries in Salzgitter. As pilot operation commences, the Volkswagen Group takes another committed step towards sustainable end-to-end responsibility for the entire value chain of the electric vehicle battery. The aim is the industrialised recovery of valuable raw materials such as lithium, nickel, manganese and cobalt in a closed loop together with aluminium, copper and plastics, achieving a recycling rate of more than 90% over the long term.

The unique feature of the Salzgitter plant is that it only recycles batteries that can no longer be used for other purposes. Before the battery is recycled, an analysis determines whether the battery is still powerful enough to be given a second life in mobile energy storage systems such as the flexible rapid charging station or the mobile charging robot, for example. Larger volumes of battery returns are not expected until the late 2020s at the earliest. Therefore, the plant has been designed to initially recycle up to 3,600 battery systems per year during the pilot phase – this is the equivalent to approximately 1,500 tonnes. In future, the system can be scaled up to handle larger quantities as the process is consistently optimised.

“Volkswagen Group Components has achieved a further step in its sustainable end-to-end responsibility for the battery as a key component of electric mobility,” asserted Thomas Schmall, Member of the Board of Management of Volkswagen AG, Technical Division, and Chairman of the Board of Management of Volkswagen Group Components, and added: “We are implementing the sustainable recyclable materials cycle – and play a pioneering role in the industry for a future-oriented issue with great potential for climate protection and raw material supply.”

The innovative and CO2-saving recycling process does not require energy-intensive melting in a blast furnace. The used battery systems are delivered, deep discharged, and dismantled. The individual parts are ground into granules in the shredder and then dried. In addition to aluminium, copper and plastics, the process also yields valuable “black powder”, which contains the important raw materials for batteries such as lithium, nickel, manganese, and cobalt, as well as graphite. The separation and processing of the individual substances by hydrometallurgical processes ‒ using water and chemical agents ‒ is subsequently carried out by specialised partners.

“As a consequence, essential components of old battery cells can be used to produce new cathode material,” explains Mark Möller, Head of the Business Unit Technical Development & E-Mobility: “From research, we know that recycled battery raw materials are just as efficient as new ones. In future, we intend to support our battery cell production with the material we recover. Given that the demand for batteries and the corresponding raw materials will increase drastically, we can put every gram of recycled material to good use.”

The CO2 savings are calculated at approximately 1.3 tonnes per 62 kWh battery manufactured using cathodes made from recycled material and using green electricity.

Galleria

Andreas Salewsky (r.), plant manager Volkswagen Group Components Salzgitter, and local works council chairman Dirk Windmüller commence operation of the recycling plant.

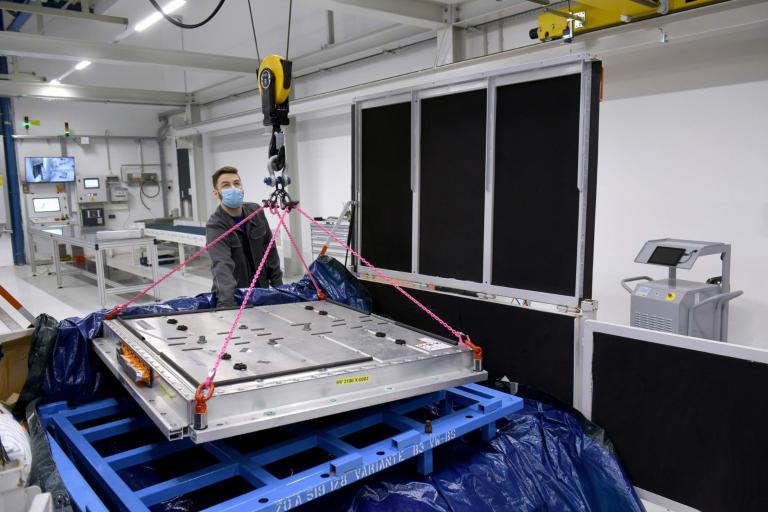

Delivery and repackaging of used high-voltage battery systems for acclimatization.

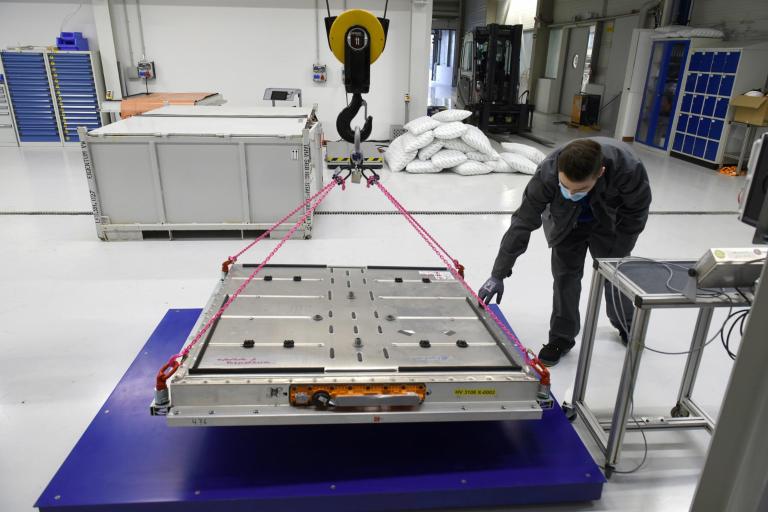

Weighing and visual inspection of the high-voltage battery systems to prepare for the next steps.

Checking and discharging: The batteries are totally discharged to recover the energy and to eliminate any risks. The batteries can be re-used if they are in a good condition.

Disassembly: The battery systems are disconnected from all add-on parts and disassembled into their individual modules.

Disassembly: The battery modules are recycled if the batteries cannot otherwise be used.

Shredder: The mechanical shredder processes the battery modules into granulate.

Sieve: The sieve is used to separate the valuable cell materials - black powder (lithium, nickel, manganese, cobalt) - from the other raw materials.

Magnetic separator and separator: The magnetic separator collects all of the magnetic raw materials from the granulate. The separator separates the residual non-magnetic metals from the remaining plastic particles.

Packaging: The extracted black powder is filled into Big Bags and prepared for onward transport for the raw materials to be separated into their individual types. The remaining materials (plastics, aluminum) are also bagged.

The raw materials obtained can be reused in a closed loop recycling process.