From the fields to the production line: SEAT Arona features components created from rice

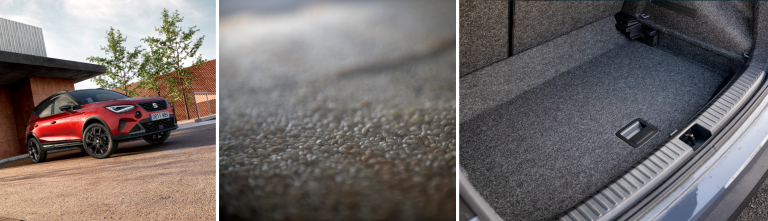

The search for sustainable alternatives for automotive components is a very topical issue. SEAT has taken an important step forward by becoming the first automotive brand to include in a production model two boot components created from Oryzite, an innovative material of renewable and natural origin, made from rice by-products after its cultivation.

This is a pilot project launched in 2020 as part of the Innovation Days of SEAT, S.A., which, after three years of research and development carried out together with Oryzite and SIGIT, now sees its culmination with full integration on SEAT Arona.

5 tonnes of rice waste reused

Opening the boot of SEAT's urban SUV, there is nothing to suggest that some components of the double-bottom support have changed composition.

In fact, what was previously made of 100 per cent polypropylene and fibreglass now includes a 15 per cent organic alternative to plastic: Oryzite, a material that can be mixed with other thermoplastic compounds and moulded.

In fact, what was previously made of 100 per cent polypropylene and fibreglass now includes a 15 per cent organic alternative to plastic: Oryzite, a material that can be mixed with other thermoplastic compounds and moulded.

‘For every SEAT Arona that comes off the production line, 60 grams of rice husks are used, the equivalent of about five tonnes per year, from the rice fields of the Ebro Delta, a biosphere reserve on the east coast of Spain,’ explains Gerard Suriol, a member of the Interior Development team at the SEAT S.A. Technical Centre.

Win-win choice

‘We were able to successfully include this renewable material and thus promote the circular economy while decreasing the use of petroleum-based products,’ Suriol continues.

This 15 per cent Oryzite brings with it additional benefits, such as a 5.8 per cent reduction in component weight and up to two per cent lower production costs.